Why Are Pond Liners Necessary?

You have a vision. For your backyard, your farm property, or for that parcel of woods out in the country that just begs for a fishing pond and a weekend campsite. Water features like ponds or small lakes can add aesthetic value, property value, and plenty of entertainment value and you’re ready to act on that inspiration. So, the very first practical question that occurs to you (or perhaps to your skeptical spouse) is: how do you make a pond out of dry land?

Perhaps once, perhaps a hundred times, most children grew up having the chance to play with a bucket of water and a bit of dirt, creating landscapes for tiny fantastical creatures that include tree-bark houses, mushroom-cap tables, and expansive lakes and rivers. While the tiny houses and tables may be there when the children return the next day, rivers and lakes are inevitably gone, soaked into the ground or dried up in the intense sunshine and summer’s heat. How will your pond’s fate be any different?

In truth, no natural lake is immune to water loss, whether from outflow into a river, evaporation, seepage, or usually a combination of those effects. The reason natural lakes persist is that the water that escapes is replenished more quickly by inflow from rivers and streams, precipitation or other surface runoff, and groundwater sources like natural spring.

When you’re constructing a pond, you’ll need to plan whether you want a seasonal feature that fills up only during the rainy season and gradually dries out the rest of the year, or if you want one that will support fish and plants that you can enjoy all the time. We’re going to assume that people reading this resource will opt for the latter. So, let’s talk about what that means.

Keeping water in place means that you want to eliminate, minimize, or control the ways it can escape. In the case of ponds, whether you’re considering a backyard koi pond or a remote fishing pond, that means preventing water from escaping by flowing to a lower spot in the surrounding land, or from simply seeping away into the ground. Evaporation can be another significant source of water loss, and there are ways to mitigate that process, but that’s not the focus of this particular resource. Deeper ponds and judicious use of shade can help get you started, though.

You can prevent water loss, from outflow, by siting your pond in a relatively low part of the terrain, or by building up walls or berms on the lower side. Again, this isn’t the focus of this e-book, but you may find some helpful information in BTL’s Learning Center. You may want to start off with a brief article on choosing the best location.

Water loss, through seepage, is one of the most persistent problems with constructed ponds and it can spell the death of an entire project if not carefully considered from the very start. Many people assume that if they have persistent drainage problems in a low point of their yard, that’s the perfect site for a pond, since “it’s full of water half the time anyway.” The key phrase here is “half the time.” You need a pond that holds water all the time. There are risks, too, from relying on surface water drainage to keep your water levels up—surface water runoff can contain chemicals and contaminants that may kill your fish or trigger unsightly, smelly algae blooms.

All things considered, your best bet with a constructed pond is to focus on preventing the water from seeping away through the soil. That’s where most ponds suffer, and it’s honestly the easiest option to fix if you consider which solutions best fit your needs.

Pretty much all backyard ponds these days are built with some sort of impermeable liner. There are many types of liners to choose from, ranging from natural clay to rigid preformed plastic shapes. We’ll be going into a lot more detail, but there are a host of additional benefits to consider when choosing your liner type.

High quality, durable liners can not only keep water in the pond where it belongs by preventing seepage. They can also:

- Help keep your fish healthy by maintaining water quality.

- Mitigate conditions which promote algae growth

- Minimize time and effort spent on maintenance

- Simplify the construction of adjoining streams and waterfalls

- Prevent chemicals like fertilizers and pesticides from leaching into your pond and injuring your fish and plants.

- Increase the longevity of your pond by minimizing the effects of weathering, erosion, and saturated soils.

- Prevent invasive plants or roots from spreading within the pond.

- Increase property value by showcasing an attractive, well-maintained pond.

So Many Kinds of Pond Liners

There are dozens of types of manmade ponds out there - some may be municipal or commercial water features installed for simple aesthetic appeal. Others ponds may be intended for local cooling effects when used in conjunction with a fountain or waterfall, while some are residential stormwater retention ponds, often outfitted with a fountain or two. Many botanical gardens have water garden sections, and museums devoted wetlands of all types can be found all over the world. Professional koi breeders, recreational fishing centers, and even businesses that offer wakeboarding and other watersports need ponds that are reliable, clean, and easy to maintain.

Then there are the rest of us - gardeners who want to create a haven of bog plants for pollinators and dragonflies, or urban enthusiasts who dream of a backyard pond full of colorful shubunkin goldfish.

For each of these purposes, there are a variety of liner options that can be employed to keep water in its place and to protect the pond and its denizens from harm. In most cases, pond liners can be categorized by the material used, which allows us to review the strengths and weaknesses of each choice, especially as they apply to the many types of ponds. Let’s dive in!

Concrete

The traditional material for swimming pools around the world, concrete can also be used to create an impermeable base for your pond. It’s strong, highly resistant to erosion, and may remain functional for up to 50 years. Thus, it will be a permanent feature of your yard, since it would take time and money to remove it. If you’re a new pond enthusiast, this is something to keep in mind. If you decide to sell your home, want a different size or shape, or there are design flaws in your original installation, a concrete-lined pond could become an expensive problem.

Concrete ponds should be professionally installed and cured to guarantee a high quality, long-lasting feature. This will increase both time and expense during startup, but custom details like complex inside contours can be included to accommodate shelves for plants, and sheltered spaces for fish to hide from predators or hot weather. Concrete ponds can be built as large and as deep as you like, and in pretty much whatever shape or even color you like. Although, since fish and plants may find the concrete surface to be too rough, you may ultimately have to cover it with a second pond liner for their protection. That would increase your costs further and certainly eliminate the advantage of custom colors.

Two other factors should also be considered. First, concrete is a naturally porous material, meaning it’s riddled with tiny, microscopic holes or crevices that allow liquids and air to penetrate it. These holes and crevices are surfaces where algae can easily build up, and once established, it can never be completely eliminated. While some microscopic algae is necessary in a healthy pond, many pond owners object to the greenish tint of algae-covered walls. If you prefer pristine white or bright colored walls, expect to be faced with tedious scrubbing sessions to keep emerging algae under control.

Finally, due to the chemical makeup of concrete, these ponds will typically have higher pH levels (more alkaline) during the first 3-5 years as the material continues to cure. For an experienced pond owner, this can be managed with careful chemical balancing and judicious use of additives, but a novice may be more comfortable consulting with a pond expert until they get the hang of things.

Preformed pond liners

Preformed liners are generally non-flexible and are available to purchase in relatively few predetermined shapes and sizes. Since these characteristics are set during manufacturing, it’s not possible to change them and it can be quite difficult to make even minor adaptations. This marks one of the primary disadvantages of preformed pond liners: once purchased, your pond design is set in stone. Anything from minor adjustments or expansions to wholesale redesigns, all require purchasing and installing an entirely new liner.

Preformed pond liners are typically made from either molded fiberglass or plastic. For square, circular or rectangular ponds (often used in modern or formal designs), box-welded liners can be custom fabricated from flexible geomembranes.

Plastic

The average lifespan of a preformed plastic pond liner is ten years. A few may make it to the 15-year mark, but many won’t even last 10 years. Plastic liners exposed to sunlight become weak and brittle over time and are vulnerable to cracking. When a rigid plastic pond liner fails, not only must the original liner be torn out, but the process of installing a new liner is just as much work as starting from scratch.

Rigid pond liners have a shorter lifespan than flexible options largely due to imperceptible (to us) ground movement. This movement may be due to ground settling, nearby disturbances to the soil or the water table, frost movement, and yes, minor earthquakes. As the plastic ages and becomes brittle, even minor ground movement can cause cracking and serious, irreparable leaks.

Installation of a plastic pond liner sounds simple - dig a hole and drop it in, right? Yet, as in many things in life, the reality is much more complex. While these liners are stiff, they’re not particularly strong, and it’s imperative to evenly support every inch of the plastic shape to prevent warping and eventual cracking. A correct installation involves covering the bottom of the hole with a generous layer of sand before the form is placed, then filling in gaps between the soil and the liner with sand at the same time it’s filled with water. The added weight of the water helps eliminate gaps and prevents shifting during installation. The pond form must also be meticulously leveled as the hole is backfilled. This process takes time and careful attention to detail.

Another frequent issue with preformed plastic or fiberglass liners is their limited size and depth. Transportation becomes quite expensive proportional to the number of units in a single shipment, so large and deep pond forms quickly become unprofitable for manufacturers. In fact, most preformed liners have a maximum depth of 18-24 inches. Such shallow ponds may work quite well for a garden pond that will feature only a variety of plants, but it usually won’t support a healthy fish population. Shallow ponds not only lose a lot of water due to evaporation, but the water quickly warms up (and cools down) as the outside air temperature changes. Without the ability to seek deeper areas to escape temperature extremes, cold water animals like fish rapidly become stressed and may even die in the span of a single hot day. Shallow ponds also leave their occupants vulnerable to predation from wildlife. Birds, raccoons, and even domestic cats can easily see and reach to the bottom of the pond, and the fish literally have nowhere to hide. Not much is more discouraging to find that your lovingly installed pond has been completely decimated in just a few hours.

Fiberglass

Fiberglass, as a material, is quite rigid, making preformed fiberglass liners strong enough that they can be placed directly on top of the ground and filled with water - no digging required. Landscaping or a decorative enclosure can be added for an attractive appearance, and fiberglass is quite durable so it can be expected to last for up to 30 years, even full exposed. Preformed fiberglass shells are still somewhat limited in depth and shape, and factory customization is all but impossible, unless you’re prepared for premium pricing.

Nowadays, some newer fiberglass liner types can be customized, so they don’t actually fall under the classification of “preformed”. In these cases, the liner is installed as a flexible matting that can be molded to any shape to match the contours of the hole. Once placed, the matting is hardened and made waterproof by applying resins. The resin coating has a smooth texture that doesn’t allow algae to stick and is available in a multitude of colors. However, it’s important to remember that only some resins are approved as safe for fish and wildlife and the cost of professional custom installation can be significant.

Because fiberglass liners are generally much more expensive, this option is usually best suited for highly dedicated pond owners, or commercial shops needing a feature that can be quickly set up above ground and emptied and moved between seasons.

Box Welded

Box welded liners are made from flexible geomembranes and custom fabricated in the factory to exact dimensions. The liner material is heat welded to melt multiple layers together, forming a regular shape like a square or rectangle. Some fabricators also offer circles, but box welding isn’t suitable for irregular shapes and lines. Box welded liners arrive folded up and since it’s a relatively simple matter to unfold them and simply drop them into the prepared hole and anchor the flaps, installation is simple.

Since the material itself is flexible, these liners are much less prone to cracking, and some high-quality materials are even rated for storing drinking water - an absolute assurance that they’re safe for your fish and plants. BTL Liners offers box welded liners fabricated from the AquaArmor line of reinforced polyethylene materials. Give us a call and we’ll help you set up your order!

Box welded liners are much less expensive than fiberglass, but more expensive than rigid plastic liners. Their lifespan is also in between the extremes, but they share similar restrictions as far as shape goes. If your landscaping plan allows for very formal rectangles, this might be a good option for you, but those seeking a more natural look probably won’t be satisfied.

Flexible Pond Liners

Flexible pond liners are on the affordable end of the scale and are well adapted to irregular and unique pond shapes, as well as underwater shelves and depth changes. Flexible liners are relatively easy to install and even large ponds can be fully lined in a single day. Even better, flexible liners are easy to customize and make changes to, even after the liner has been in use. No other type of liner is suited as well to expanding your pond, adding a waterfall, or even changing the shape without needing to dig up and replace the entire pond.

The important thing to know is that the term “flexible geomembrane liner” encompasses a variety of materials, whose chemical makeup and physical characteristics vary quite a bit. If you’re leaning towards a flexible pond liner, look at our section Much Ado About Flexible Materials, where we talk in depth about the strengths and weaknesses of a variety of different types of flexible pond liners, including EPDM and RPE.

Natural Clay Liners

Some environmentally conscious pond enthusiasts prefer to use liners made entirely of natural materials, and this means clay. Clay liners mimic the way ponds and lakes form in nature.

Clay, or bentonite, liners must be custom installed, and the process can be demanding. It involves applying two or more layers of material which must be carefully compacted to eliminate air pockets in order to create a durable, watertight seal. Limestone and clay layers are the most practical for small pond owners since compacted clay alone must be very thick to achieve a durable watertight seal.

Usually, a clay and limestone liner (often called lime concrete) begins with covering the walls and floor of the excavation with a layer of limestone, which is in turn covered with a layer of bentonite clay. When applied correctly, this combination is waterproof and is also fairly durable, but it is still vulnerable to erosion. Clay liners must also remain moist in order to maintain their integrity. Once clay dries out, it shrinks and cracks, and even if it’s wetted again, the cracked clay will no longer seal, making it very difficult or even impossible to repair.

If you must drain your pond for any length of time (even for as little as a few hours in hot, dry weather), care must be taken to keep the exposed liner moist. You can do this by covering the exposed clay with a good layer of mulch or straw.

Overall, clay liners require more upkeep than most, but when properly cared for they can last for years. On the aesthetics side, due to the nature of clay, some amount of persistent silt and debris in the pond bottom, or possibly even suspended in the water column should be expected. This can be a good option for pond owners seeking a very natural look, but if crystal clear water is your goal, you’re not likely to get it with clay.

Cheap Alternatives to Liners:

As we’ve seen, many impermeable materials are available as pond liners, and while many are relatively inexpensive, some budget-minded enthusiasts may opt to cut corners even further by using or reusing tarps, deflated pools or waterbeds, or roofing membranes. Unfortunately, these are usually questionable choices, with some releasing toxins into the water, and others prone to rapid degradation from sun exposure or troublesome leaks from poorly sealed layers.

What are All These Layers?

Today, flexible geomembranes, as a class, are thin, continuous sheets of synthetic polymers, usually referred to simply as plastic. Specific geomembrane materials may be derived from different types of polyethylene, polyvinyl chloride, or a combination of materials. The ultimate characteristics of a polymeric membrane are determined by the types and structures of the polymers, i.e., branched chains, which produce a product which is slightly denser and stiffer, such as HDPE, and short chains, which produce a product which is slightly more elastic, such as LDPE. The specific molecular structures are selected for by adapting the manufacturing process using heat, pressure, and a variety of additives.

Engineered Coatings

How Coatings are Used

A simple HDPE or LDPE membrane has its own unique characteristics, but sometimes even then, the material isn’t an ideal fit for a specific application. In these cases, it may be that combining two different materials would allow them to share properties, and the end product may reflect the desired characteristics while eliminating or reducing the undesired ones. In pursuit of these combinations, scientists have developed ways to merge two (or more) polymer materials to produce a geomembrane that is, ultimately, better than the sum of its parts.

Today, an increasing number of high-quality pond liners are manufactured by starting with a base material, or scrim, which offers strength and tear resistance, which is then encapsulated with engineered coatings that contribute other qualities such as impermeability, flexibility, puncture resistance, and UV resistance.

Reinforced Polyethylene (RPE) liners are typically constructed of layers of HDPE and LDPE. They’ve been around for years, and are widely recognized for their outstanding strength, durability, UV and chemical resistance, and more recently, for their affordable price.

PVC membranes have recently been introduced with new coatings that increase their lifespan and eliminate longstanding concerns with the use of liquid plasticizers. However, this new material is both expensive and highly specialized, best suited for use in hazardous material containment and other chemically challenging applications.

EPDM pond liners are single ply membranes and are not offered with coatings.

How Coatings are Applied

Engineered coatings are added to geomembranes during the manufacturing process, and the method varies according to the materials and the membrane’s ultimate application. Some coatings are sprayed on, some are fused through calendaring, and others are co-extruded as a single sheet.

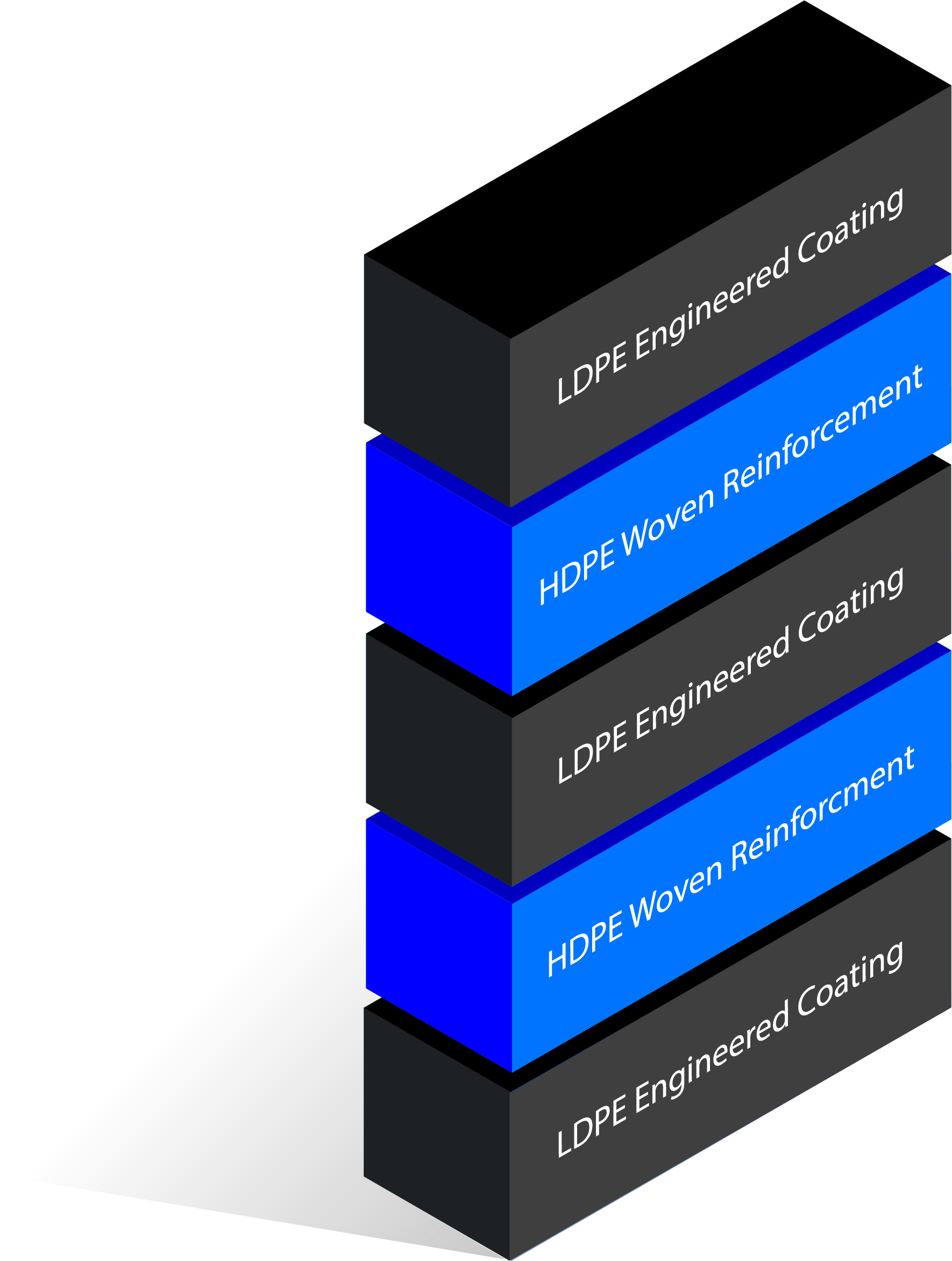

All BTL AquaArmor geomembranes are co-extruded. They’re produced by sandwiching one or more reinforcing layers, or scrims, between layers of LDPE. This “sandwich” is passed through a series of rollers, which apply heat and pressure to melt the LDPE and permanently bond it to the scrim. Since the layers merge into each other in a molten state, they are permanently joined and cannot delaminate. The final product is a strong and durable geomembrane with excellent resistance to punctures, tears, and UV radiation.

Scrims / Woven Reinforcement

In reinforced polyethylene geomembranes, the choice of scrim material affects the characteristics of the final product. BTL uses a woven HDPE layer in nearly all AquaArmor products. This HDPE scrim is tightly woven with no gaps between the individual tapes. Our PP-45 product, however, uses a woven polyester scrim. Polyester scrims are not tightly woven, and spaces are visible between each “thread.”

Both scrim choices produce excellent geomembranes, with slightly differing qualities. The correct choice for your application depends on which characteristics are most important to you.

Geomembranes using woven HDPE for the reinforcing layer are less expensive than other geomembranes. Since HDPE has inherent resistance to UV exposure, it won’t deteriorate as quickly when exposed to sunlight. However, HDPE is relatively stiff compared to other polyethylenes, which can make it slightly more difficult to install in some situations.

Geomembranes that use woven polyester for the reinforcing material are inherently more flexible and have superior tear resistance, making them a better option in situations where high strength is particularly important. However, polyester is more vulnerable to UV exposure and in some cases can deteriorate more rapidly.

UV Resistance

Why is the Sun a Problem?

Pond liners are often exposed to sunlight, even with carefully constructed borders. When a pond’s water levels drop due to evaporation, the top of the liner can peek out above the waterline where the sun can reach it. In other cases, maintenance or repair activities may require lowering water levels by a significant amount. Brief UV exposure doesn’t seem likely to destroy most pond liners, but once damage occurs, it’s progressive. If you’re hoping for a pond that will last for years, any type of damage will inevitably shorten the liner’s lifespan. If you’re building an irrigation pond which could be at least partially empty for several months out of the year, for example, UV resistance is absolutely a critical factor in your choice of material.

Unfortunately, there is a lot of unclear and sometimes conflicting information on the internet regarding UV resistance of different materials; even from manufacturers themselves. HDPE, LDPE and LLDPE can be described as the best or the worst in UV resistance, depending on which resource you check. We’ll try to clear up some of the confusion here.

Molecular Structure

When comparing HDPE, LDPE, and LLDPE in their most basic forms, LLDPE (linear low density polyethylene) is considered to be the most resistant to UV damage. The resistance is derived from its molecular structure, which contains a high proportion of relatively short linear polymer chains, which are very stable and less susceptible to disruption from UV rays. LLDPE is also denser than LDPE and has a higher tensile strength, which allows it to maintain an acceptable level of performance even if some of the polymer chains are damaged.

In terms of UV resistance, HDPE falls somewhere in the middle. Instead of long linear chains, HDPE is made of large branching structures of polymers. These branches form a dense, compact structure, making the material less vulnerable to UV radiation, as well as stronger and stiffer, but ultimately the branching structure is not quite as stable as long chains.

Among these 3 types of polyethylenes, LDPE is considered the least resistant to UV degradation. LDPE has a comparatively open molecular structure, as well as a low molecular weight, which allows UV rays to penetrate the material more easily. UV light can break down the long polymer chains, eventually producing a material that’s weak and brittle.

How does UV light do so much damage? Within the spectrum of energy emitted by the sun, the short wavelengths of ultraviolet light have higher photon energy compared to other wavelengths. When absorbed by polyethylenes, if the photonic energy is greater than the molecular energy that holds the chains together, the molecular bonds will split, a process known as oxidative degeneration. As the bonds break down and release free radicals, a train of destruction begins which continues to spread, even absent further exposure to UV rays. This process leads to a steady decline in physical strength, flexibility, and durability, inevitably reducing the useful lifespan of the material.

UV Stabilizers

So, you may wonder, how can BTL and polyethylene manufacturers offer UV warranties for liners that are exposed to sunlight? UV stabilizers are the answer. The fact is, geomembranes for pond liners are nearly always manufactured with the addition of carbon black, a highly rated UV stabilizer. In action, carbon black absorbs both visible and UV rays and transforms them into less harmful thermal energy. This stability can last for decades, making UV warranties possible, even for applications where the material is constantly exposed to sunlight.

Carbon black is typically added to polyethylenes in concentrations of 1%, 2%, or 3%. (After 3%, the UV protection tapers off.) All BTL-designated single-scrim geomembranes in the AquaArmor Line contain a minimum of 3% carbon black for maximum protection, while the RPEL-30 geomembrane, in addition to carbon black, includes a clear LLDPE film coating which provides even more robust protection. Our thicker double-scrim products, on the other hand, reap the benefits of their multi-layer construction.

Our BTL, PPL, RPEL, and PP Lines

(Layering for: AquaArmor BTL-20 - BTL's single scrim products are thin, lightweight, very flexible, and offer warranties against UV damage even in exposed conditions.)

(Layering for: AquaArmor BTL-20 - BTL's single scrim products are thin, lightweight, very flexible, and offer warranties against UV damage even in exposed conditions.)

(Layering for: AquaArmor PPL-24 - BTL's double scrim products are built with durability and longevity in mind. These liners are moderately thick, offering exceptional durability against punctures, tears, and abrasion. The double scrim reinforcement conveys excellent UV protection, and each product offers a 20-year warranty against UV damage, even in exposed conditions.)

(Layering for: AquaArmor PPL-24 - BTL's double scrim products are built with durability and longevity in mind. These liners are moderately thick, offering exceptional durability against punctures, tears, and abrasion. The double scrim reinforcement conveys excellent UV protection, and each product offers a 20-year warranty against UV damage, even in exposed conditions.)

(BTL’s RPEL-30 product is a relatively thin, single scrim product enhanced by an additional layer of highly UV resistant LLDPE. This film offers great stability against UV damage, even in exposed conditions, while maintaining the exceptional flexibility and light weight of our thinner products. This is an exceptional value for agricultural irrigation ponds where water levels may fluctuate significantly from season to season. This product is also well suited for many hydroponic and aquaponic applications due to its superior hydrostatic resistance. )

(BTL’s RPEL-30 product is a relatively thin, single scrim product enhanced by an additional layer of highly UV resistant LLDPE. This film offers great stability against UV damage, even in exposed conditions, while maintaining the exceptional flexibility and light weight of our thinner products. This is an exceptional value for agricultural irrigation ponds where water levels may fluctuate significantly from season to season. This product is also well suited for many hydroponic and aquaponic applications due to its superior hydrostatic resistance. )

(BTL’s PP-45 product is unique among the AquaArmor line in that it uses a woven polyester scrim and one side of the material is tan rather than black.)

(BTL’s PP-45 product is unique among the AquaArmor line in that it uses a woven polyester scrim and one side of the material is tan rather than black.)

Much Ado About Flexible Materials

What is a mil?

You’ll find a surprising number of pond liner websites that refer to the thickness of their pond liners in units of millimeters. This is a surprising mistake, because mm and mil are vastly different sizes! To understand why this is such an important distinction, let’s start with a simple conversion: 1mm = 39.4 mils. Or, 1 mil = 0.03 mm.

For our US customers, 1 mil is 0.001 inches (one thousandth of an inch). Another way to visualize it is that ⅛ inch (about 3mm) is equal to 125 mils. 125 mils is more than twice as thick as the strongest liner we sell.

Let’s consider some comparisons:

30 mils is a popular thickness for most RPE pond liners - it’s reasonably strong and yet lightweight and flexible, ideal for most backyard ponds. For reference, it’s about the thickness of a credit card.

Some websites will quote this as 30mm, which should set off alarm bells in your head! Imagine trying to install a liner that’s over an inch thick!

The thickest liner we sell, suitable for the most challenging applications that require high strength, durability, and long lifespan, is 60 mils. For reference, that’s about the thickness of a penny. 60mm, on the other hand, converts to over 2000 mils, and is approximately the size of a skateboard wheel.

Keep these differences in mind as you consider different liner sources. (Nobody actually offers 60 mm thick polyethylene pond liners.)

Through Thick and Thin

In any sheet material you consider, thickness is directly related to the product’s strength and toughness, whether you’re looking at a paper towel, aluminum foil, or a painter’s tarp. The same is true for geomembranes, and since these materials are used in a wide variety of applications with differing demands, they’re available in a range of thicknesses.

While the choice of material and construction of a given geomembrane has an even greater effect on the final qualities of the material, it’s reasonable to consider early on what your needs are in relation to thickness.

Geomembrane pond liners start at about 18-20 mils thick and typically top out at about 60 mils for all but the most extreme applications. In general, when you’re looking at the same material composition, the thinner examples will be lighter and more flexible, but won’t be as durable as their thicker counterparts. A thicker liner will naturally be more resistant to punctures and tears, and even UV radiation.

Keep in mind, though, that the material is ultimately the most important determiner of durability. A 45 mil EPDM liner is considerably thicker than an RPE liner that offers similar strength, tear resistance, and durability.

HDPE

Single ply HDPE geomembranes have historically made popular pond liners because of their low price, strength, and resistance to tears, along with the ability to heat weld multiple sheets for extremely strong, leak-free seams. However, HDPE on its own is relatively stiff and heavy, and can be expensive to ship and difficult to install. It’s also vulnerable to punctures and damage over time from scuffs and superficial scratches.

Today, HDPE geomembranes are more commonly used for chemical containment and landfills than fishponds, because of their excellent chemical resistance. There are other inexpensive options that are better suited to the specific needs of most fishponds.

LLDPE

Even though HDPE and LLDPE are both polyethylene plastics, they have different molecular structures, giving them different physical properties. It’s important to keep these differences in mind because these properties will ultimately determine how well a liner meets your needs.

Compared to HDPE, LLDPE is much more flexible and can be stretched and folded easily to conform to your pond’s shape, making it easier to install with fewer wrinkles. Because of its softness, LLDPE can be folded without damage, making it easier to package and ship, even in extremely large panels.

Pricewise, LLDPE is generally comparable to HDPE, but it also offers higher UV resistance than its HDPE counterpart. Look at our discussion of UV Resistance for more details on how that works.

LDPE

LDPE represents a kind of middle ground between HDPE and LLDPE for most of the characteristics we’re concerned with, including flexibility and strength, although LDPE can’t withstand elongation (lengthwise stretching) as well as LLDPE.

For UV resistance, however, plain LDPE comes out on the bottom of the stack, since it is a clear or translucent material and therefore unable to deflect or absorb the energy from UV rays. However, the addition of carbon black contributes significantly to its durability, and some manufacturers will rate LDPE much higher on the UV resistance scale based on the addition of these stabilizers. For more information about carbon black, check out our discussion of UV stabilizers.

RPE (Reinforced Polyethylene)

Because RPE has become such a popular pond liner material, merchants sometimes refer to it simply as HDPE (see above for information on unreinforced HDPE liners). Here at BTL Liners, however, we usually refer to our AquaArmor line of pond liners as RPE (Reinforced Polyethylene) geomembranes. Compared to single polymer materials such as HDPE, LDPE, and LLDPE, RPE is composed of several types of polyethylene. Those specific types may differ from product to product, but each layer contributes a key property that improves the final product’s overall performance.

The reinforcing layer in our AquaArmor RPE liners is a scrim of tightly woven, prestressed HDPE tapes. During manufacturing, this scrim is co-extruded with layers of LDPE resins on both sides. The process of co-extrusion combines materials together to form a single film structure which, in this case, makes the liner impervious to water, and increases flexibility. The HDPE scrim makes the product extremely strong and resistant to both tears and punctures. LLDPE layers convey exceptional UV resistance.

Now that it’s been around for a few decades, RPE has gained an excellent reputation for strength, durability, and ease of use. Nowadays, it’s considered to be one of the best, most affordable choices among flexible pond liners. The combination of a tightly woven HDPE reinforcing core and impermeable LDPE coatings gives the liner exceptional puncture resistance - better than single layer HDPE, EPDM or PVC liners, even though the material is half as thick and one third the weight. As a bonus, RPE’s exceptional strength and durability means that underlayment is not required, a significant savings over EPDM and other more vulnerable materials. Combined with carbon black, RPE offers excellent resistance to UV radiation.

BTL’s RPE liners are lightweight and flexible, making them easy to ship and install. They conform well to complex pond shapes, without risk of deforming, and can be fabricated in extremely large sheets. The ability to order extremely large sheets allows you to cover all but the largest ponds with a single panel, reducing your risk of imperfect seams to zero. Since RPE is thermoplastic, seams and joints that must be done on-site can be handled with a heat gun, which creates a permanent weld that’s stronger and more stable than adhesives and liner tapes used for other materials.

RPE has a very high strength-to-weight ratio, making it extremely resistant to tears and scuffs. Excellent dimensional stability means the pond liner will retain its shape even when exposed to extreme temperatures, stretching, or other stresses. In fact, when properly installed and maintained, a quality RPE liner can last upwards of 40 years.

One exceptional example is our proprietary PPL™-24 product, a 24 mil RPE with a 5-layer construction; triple layers of LDPE coatings sandwich two layers of HDPE woven scrim. This robust construction results in an extremely puncture and tear resistant, yet lightweight liner material. BTL originated and developed the PPL™ line and is the nation's sole source for this product.

EPDM

EPDM (ethylene propylene diene monomer) is a synthetic rubber that has long been one of the most popular flexible geomembrane pond liners, despite its comparatively high price. Because it’s a soft, extremely flexible material, it folds easily around corners without losing strength and works well with irregular pond shapes, although it’s not generally the best option if your design includes tight corners. In comparison to other materials like PVC, EPDM is very tolerant of cold and won’t lose its flexibility or develop cracks even during extreme winter conditions, making it a good candidate in the Upper Midwest and other regions where extreme arctic blasts are possible. EPDM is only moderately puncture resistant, so it requires an underlayment, which is an added expense, but it has good endurance against UV rays, ozone, and other weathering effects. BTL’s AquaProFlex EPDM pond liners are also certified as fish and plant safe.

To offer the best performance, EPDM geomembranes are generally thicker than RPE. For example, BTL’s 45 mil EPDM liner is comparable to BTL’s 30 mil RPE liner. EPDM is also naturally heavier than RPE. Because of these factors, EPDM isn’t supplied in extremely large panels since it would be too heavy and unwieldy to transport and handle, even with heavy machinery. Limited panel size isn’t an issue for small and moderate size ponds, but in the case of very large ponds, installers are forced to join multiple panels together on-site.

EPDM is a thermoset membrane, meaning that it can’t be heat welded without losing important qualities like flexibility. That means that EPDM panels must be seamed together using tapes and adhesives. For a large pond, joining multiple panels with many seams is a time-consuming task, and every seam represents one more potential failure.

EPDM enjoys a long-standing reputation as a high quality and reliable pond liner, and many experienced professionals and hobbyists continue to recommend it above any other, although it’s relatively high price point (including shipping) has allowed newer options like RPE to make inroads on its market share. We’ll go into more detail with pricing comparisons in our section on Pondering the Budget, which provides helpful details.

PVC

PVC (Polyvinyl Chloride) is a long-established pond liner material, popular based largely on its very low price and flexibility, although in the last decade it has significantly faded from popularity due to concerns with toxic plasticizers like phthalates leaching into the water. In some countries, PVC film was banned for use in food packaging.

The fact is, all PVC products contain plasticizers, since on its own, PVC is hard and brittle. In fact, it’s actually plasticizers and stabilizers that give the membrane its exceptional malleability. More recently, manufacturers have sought to identify and use fewer toxic plasticizers in their products, but even now, some cheaper pond liners contain trace amounts of arsenic and other chemicals that are toxic to fish, due to exposure during the manufacturing process.

Many prospective pond owners on a budget consider using PVC liners because of its low price point, but it’s still important to weigh the cheaper price upfront against PVC’s short lifespan. PVC is vulnerable to weathering from UV and ozone exposure, and plasticizers are prone to leaching out which leaves the liner brittle and vulnerable to damage. PVC has the shortest life expectancy of all modern liner materials, and typically must be replaced every 10 years, compared to other products with expected life spans of 30 years or more.

To maximize the lifespan of a PVC liner, it’s particularly important to shield it from exposure to air and sunlight. Most manufacturers recommend that PVC be buried under at least 12” of soil or sediment, which can be difficult to achieve in your average backyard pond. It’s also important to install an underlayment, which may significantly reduce the original cost savings.

Pondering the Budget

Setting up a budget for your pond project really should come first—before you even start clearing out a space in your yard or visiting local pond suppliers to price equipment. After all, unless your pockets are bottomless, there will probably be some compromises to be made and it’s a good idea to have your priorities in place before you fall head over heels for the latest Pond Emperor Pro 10K™ all-in-one pond pump/aerator/waterfall/lawn mower.

How Much Does It Cost to Line a Pond?

Fair warning: this isn’t really a fair question - either for you or for your pond supplier. Estimates that you’ll find online give very little useful information and are probably less informative than throwing a dart at a wall full of random numbers. Why? Because every pond is unique in size, shape, location, features, and special circumstances, and very few liners are directly comparable when it comes to pricing. Trying to compare a custom installed fiberglass liner to self-installed EPDM with underlayment or a pre-formed plastic liner is akin to comparing apples to oranges, strawberries, or even tricycles.Let’s look at some of the most obvious pricing factors:

iner type and size

Premium fiberglass or concrete pond liners not only cost more than most flexible geomembranes like EPDM (synthetic rubber) or one of the polyethylenes, but they have different installation requirements. Professional installation and a variety of options can add significantly to the price, while still falling under the “liner” expense category. Protective options like underlayment or installation necessities like sand, on the other hand, are not included in the price of the liner itself. There are so many variables, in fact, that one major website lists “pond liner prices by material” as ranging from a low of $0.20 to $130 per square foot.

Rigid Preformed Liners

Preformed liners are priced on their own set of measurements, and they’re inevitably higher, usually due to shipping costs, whether that’s charged separately or folded into the price of the liner. The cost may increase significantly if you choose a shape that has plant shelves or other shape complexities.

HD Polyethylene 270 gallons ~$450 at Local big box home improvement

Fiberglass 215 gallons ~$1110 from pond supplier *plus freight charges

Flexible Pond Liners

Pond liners made from flexible geomembranes are priced by square foot and it’s possible to purchase standard, pre-cut liners or order custom cut sizes through specialty fabricators like BTL Liners. Your local pond store may also be able to source custom sized liners, or there are typically a few options in limited sizes at a big box home improvement store,

Since flexible pond liners offer nearly infinite flexibility in pond designs, the important part with these liners is to correctly measure your pond - length, width and depth, since liner sizes can be deceiving. A 10x10 liner will cover a surprisingly small pond, for example. Check out our chapter Measure Twice, Order Once for detailed instructions about calculating the right size liner!

Most liner fabricators offer lower prices per square foot as the size of the liner increases. Keep in mind that BTL Liners can make single panel liners as large as 150,000 square feet, the largest in the industry, and we have experience in installing reservoir liners as large as 500,000 sq feet. No matter the material, unit prices will certainly vary from one extreme to another, so to get the most accurate pricing information, be sure to request an online or telephone quote from our team of experts.

Here are prices for pre-cut sheets in a few popular products. The table shows the specific product, the flat dimensions of the liner, an approximate size for the pond it would line, the approximate volume (use our volume calculator for a more detailed calculation), and price.

BTL-24 - 560 gal $110-$150

Flexible geomembrane liners are available in a potentially bewildering array of materials and options. Check out more detail in our sections Much Ado About Materials and Selecting the Right Pond Liner. Each option you choose, including the specific material, thickness, and any special coatings can affect the final price. It’s always best to call BTL Liners for an exact quote before you make your final decision.

Installation and Underlayment

Concrete and custom fiberglass ponds require professional installation, which adds to the price. If your pond will be especially deep, with steep sides, structural reinforcement will be necessary to keep the walls from collapsing.

Flexible geomembrane liners can usually be easily installed by hand, even for large irrigation ponds, although it might require a team of volunteers! Home installation for EPDM liners is also generally practical, but the material can get extremely weighty for large ponds and heavy machinery is sometimes required just to move the rolls into place and unroll them.

PVC, thin Polyethylene, and all EPDM liners require a protective layer of nonwoven geotextile to protect the liner from damage. These extra line items are typically priced separately from the liner material and will add to the actual cost of lining a pond.

Pond Liner Costs: Balancing Budget and Features

It can be overwhelming when you take a deep dive into all the possibilities for your pond. Do you choose the cheapest? The priciest? Which material will work best for realizing your dream pond? How will your budget stand up to the stress?

There’s no one who can definitively tell you, which is your best choice, but you can certainly narrow the options down by comparing the needs of your project to the qualities of the various liners and installation details. Once you’ve done that, you can compare final estimates from reputable businesses and see how they fit into your budget. Our section on Selecting the Right Pond Liner goes into detail on common concerns for most pond owners.

Finally, consider the reputation of those businesses and the level of support they offer both before and after you’ve purchased your liner. BTL Liners has years of experience in the pond lining business, ranging from small backyard ponds to 40+ acre irrigation ponds, as well as some of the most critical containment needs in industry. Check out our section How BTL Makes it Easy to see how our exceptional customer service is an industry standout!

Flexible geomembrane liners are available in a potentially bewildering array of materials and options. Check out more detail in our sections Much Ado About Materials and Selecting the Right Pond Liner. Each option you choose, including the specific material, thickness, and any special coatings can affect the final price. It’s always best to call BTL Liners for an exact quote before you make your final decision.

Installation and Underlayment

Concrete and custom fiberglass ponds require professional installation, which adds to the price. If your pond will be especially deep, with steep sides, structural reinforcement will be necessary to keep the walls from collapsing.

Flexible geomembrane liners can usually be easily installed by hand, even for large irrigation ponds, although it might require a team of volunteers! Home installation for EPDM liners is also generally practical, but the material can get extremely weighty for large ponds and heavy machinery is sometimes required just to move the rolls into place and unroll them.

PVC, thin Polyethylene, and all EPDM liners require a protective layer of nonwoven geotextile to protect the liner from damage. These extra line items are typically priced separately from the liner material and will add to the actual cost of lining a pond.

Pond Liner Costs: Balancing Budget and Features

It can be overwhelming when you take a deep dive into all the possibilities for your pond. Do you choose the cheapest? The priciest? Which material will work best for realizing your dream pond? How will your budget stand up to the stress?

There’s no one who can definitively tell you, which is your best choice, but you can certainly narrow the options down by comparing the needs of your project to the qualities of the various liners and installation details. Once you’ve done that, you can compare final estimates from reputable businesses and see how they fit into your budget. Our section on Selecting the Right Pond Liner goes into detail on common concerns for most pond owners.

Finally, consider the reputation of those businesses and the level of support they offer both before and after you’ve purchased your liner. BTL Liners has years of experience in the pond lining business, ranging from small backyard ponds to 40+ acre irrigation ponds, as well as some of the most critical containment needs in industry. Check out our section How BTL Makes it Easy to see how our exceptional customer service is an industry standout!

Selecting the Right Pond Liner

Matching Your Liner to Your Needs

Most pond enthusiasts hope to create a pond that will last for years, perhaps even generations. After all, creating a unique oasis that will be a home to playful fish or delightful flowers and the wildlife they attract is ultimately a labor of love. It only makes sense to select a high-quality liner that will protect your fish and plants from damage and stress, not to mention the frustration and expense of endless maintenance and repairs.

Since each design and location and owner is unique, the specific challenges or needs for each pond will differ as well. Consider your plans and goals, your environment, your design to help you identify your priorities and then identify the liner that best meets those needs. Here are a few common situations that may get you started:

- Some pond owners who live in cold regions plan to overwinter their cold-hardy koi and goldfish in the pond, allowing the surface to ice over and their fish to enter a state of dormancy during the coldest months. You should be able to find information about the cold tolerance of any liners that you’re considering. Some liners become stiff during extremely low temperatures and are vulnerable to cracking. Avoid those if your region tends to experience extremely cold winters. Most of BTL’s AquaArmor products have cold crack thresholds below -85°F, which should cover most locations on the planet. Detailed specifications are available with each item description.

- Pond designs that leave liners exposed to the air and sunlight require especially durable materials and even specially coated liners to reduce or avoid rapid degradation from ozone and UV rays. While both RPE and EPDM have excellent weathering resistance, thicker liners will naturally withstand exposure for longer time. All BTL’s AquaArmor series offer warranties for exposure to open air and sunlight, ranging from 5 years for our thinnest 20 mil RPE liner to 20 years for liners starting at 30 mil. BTL’s AquaProFlex EPDM liner also offers a 20-year warranty.

- Are you planning a natural pond look or a formal design? Flexible liners conform most easily to the curves and corners of a pond, whether it’s a formal rectangular shape or a wandering, naturalistic pond with several depth changes. BTL’s AquaProFlex EPDM liner is exceptionally soft and flexible, making it very easy to work with. It is thicker than other options, though, so very tight corners and curves may appear bulky. BTL’s AquaArmor RPE liners are among the most flexible geosynthetic options, though they’re not quite as soft as EPDM. However, their exceptional strength means it’s possible to use a relatively thin liner without sacrificing durability. The AquaArmor line includes two 24 mil liner options, only half the thickness of EPDM. If easy installation and close conformation to tight corners is a high priority, consider BTL-24 or PPL-24 for the best experience and appearance.

- Some types of liner are available in many colors and in some cases may be visible below the waterline. Consider the colors and textures available and how they will blend with your vision. Thicker, reinforced liners are more durable and will tolerate the addition of large stones, attractive river rocks, and pea gravel to give a more natural look. In general, dark liners are less stressful to fish since their hiding spaces feel less exposed. Dark liners also do a better job of disguising sediment or detritus that may have settled to the bottom in between cleanouts.

- Realistically, what’s the chance that you’re going to want to expand your pond within a few (or even ten) years? The pond bug, once it bites, can quickly lead to a string of expansions, improvements, and endless tinkering. If you’re likely to succumb to the temptation, keep in mind that some pond liners are more suited to remodeling. Overall, polyethylene and EPDM liners are much easier to work with than most alternatives since it’s possible to seam or weld new liner pieces together. This allows you to expand your pond while maintaining a waterproof seal. Preformed and other rigid pond liners tend to be much more challenging, if not outright impossible.

- Have you built a pond before? The most important part of installing a pond liner is making sure you have no leaks, and the best way to ensure that is to order a liner that will cover your pond in a single panel. Seams that are added on-site are much more likely to leak than a single panel or even factory seams. BTL Liners can offer the largest single panels in the industry and can fabricate custom pond liners according to your specifications. Sometimes things don’t all go as expected and you run into a difficult corner during installation. Experienced support that’s available with just a quick phone call can make the difference between a long-lasting leak-free pond and a chronic headache. Don’t underestimate the value of expert backup!

- The health and safety of your fish and plants is undoubtedly high on your priority list, so be sure to select a pond liner that’s certified by the manufacturer to be fish and plant safe. Don’t rely on a salesman or your neighbor down the street to tell you whether a liner will harm your fish. Some health effects may take quite a while to appear in your fish, and individuals unfamiliar with the manufacturing process may not be aware of additives or coatings that can leach toxins into your pond.

BTL has a variety of Reinforced Polyethylene (RPE) products that are certified as NSF/ASTM-61, suitable for storing potable water. This is the highest possible quality designation and certifies that no harmful chemicals will leach into your pond water. BTL’s AquaProFlex EPDM liner is specially formulated to be fish and plant safe.

Save Now or Save Later?

When it comes to the realities of a limited budget, you may be forced to decide to skimp on equipment, the liner, or cut the budget a little bit on everything. Before you decide on that strategy, take a moment to consider what’s harder to replace in the long run if you have to cut corners? The pump or aerator when it fails due to premature wear? Or the liner when it fails due to tears, leaks, or UV degradation? Replacing a piece of equipment is a fairly simple matter of ordering a new one from your local supplier or online retailer and plugging it in. Replacing a liner, on the other hand, may cost thousands of dollars and will certainly involve completely emptying your pond, finding a place to temporarily house your fish & plants, and investing anywhere from several hours to a full weekend of work to install the new liner, refill the pond, and cycle it. Which sounds like the better expense to defer?

How to Measure and Order

There’s more to calculating the size of your pond than measuring its length and width, and it’s important to take this into consideration early in the design stage. Not only will it determine the type and amount of pond liner you purchase, it will also dictate the equipment - how powerful your pump needs to be and what size filter will suffice. It will even dictate how many fish you can support!

Depth and Volume

What’s this mysterious additional measurement? The depth of your pond. You’ll need to know this to calculate how many gallons your pond will hold, and you might be surprised how quickly that number rises. The more gallons your pond holds, the more powerful your pump must be and the larger your biofilter should be. Both pumps and biofilters are rated according to the volume of water they’ll be handling.

The depth and volume of your pond will limit other parameters as well. Any body of water (even that 10-gallon aquarium in your den) has a maximum population of fish it can support while keeping the environment healthy. In general, the limit is 1-2 inches of fish per gallon of water. So, your 10-gallon aquarium should be able to support 10 tiny tropical fish with an average length of 1”. Koi, however, can reach a mature length of 24 inches or more, and since koi and goldfish generally produce a large amount of waste, it’s a good idea to lean to the larger size for calculations. Keep in mind that your young koi will grow as they mature, so you’ll need to either calculate based on their expected mature size or plan to cull some of them as they grow - a painful prospect for any involved pond owner.

Keep in mind, too, that a minimum depth of 3 feet is required if you’re going to overwinter your koi and goldfish. Shallower ponds risk problems with temperature regulation which can disrupt the dormancy period for your fish.

In warm climates, it’s extremely important to keep a minimum depth of 30 inches, at least in some parts of the pond. When water temperature rises, it holds less oxygen, and your fish will seek deeper sections to avoid stress. It’s a bad sign when fish start gasping at the surface to seek air—providing a deep section gives them a safe place with plenty of available oxygen to rest and escape the heat.

To figure the volume of your pond in gallons, checkout our pond volume calculator here.

The volume of your pond may also limit your liner and design options. Preformed fiberglass liners are designed to support the weight and hydrostatic pressure of the water it contains, even aboveground and unsupported. Preformed plastic liners, on the other hand, cannot maintain their shape without complete support on all sides.

Above Ground?

Flexible liners, obviously, can’t be installed above ground unless they’re enclosed in some sort of supportive structure. However, since the liner will conform to the shape of the structure, above ground installation is not only possible, but relatively common.

Of course, if you’re planning on overwintering your fish, an above ground pond should have good insulation in the surrounding structure to avoid rapid changes in water temperature. In fact, insulation is a really good idea in areas with high summer temperatures as well.

Measure Twice

Once you’ve completed the design of your pond and you’re sure that the dimensions and volume are adequate to meet your goals, it’s time to order your flexible liner. It may seem more logical to dig the hole first, but since shipping will take a couple of days and an unexpected rain shower or other disturbance can cause significant damage to your carefully prepared excavation, we recommend that you calculate your liner needs based on your plan and allow some wiggle room in case your digging isn’t very precise. Once the hole has been prepared, do a sanity check to ensure your liner covers the entire excavation with enough allowance to anchor it securely in place.

BTL’s pond calculator will calculate the amount and dimensions of pond liner you should order based on some simple measurements, but we’ll discuss a few finer details here to help you get the most accurate measurements.

Look for the Maximum

Most ponds aren’t shaped as a simple circle or square. You may have chosen a fairly traditional kidney shape or figure eight, or you may have opted for a more natural, relatively complex shape. You may also have some variations in depth. One way or another, since your pond is a three-dimensional structure, you’ll need to accommodate each dimension in your liner calculation.

You’ll be measuring length, width and depth of the hole, but when ordering your liner, you need to ensure you’re measuring the maximum reach in each case.

Pond Calculator

Width: and Length:

Measuring for Length

Using the longest dimension, plan how your liner will lay. Whether you’re using woven polyethylene or EPDM, it should lie straight without attempting to follow a curve.

Once you know how your liner will lay, measure the maximum distance from one end to the other. If you’re not sure exactly where the maximum distance is on a curved pond, take several measurements in several locations and use the longest value.

Measuring for Width

For the width, measure perpendicular from the layout of your liner. Again, measure several points if it’s not immediately clear where the widest point is, and choose the largest measurement.

Measuring for depth

Once you know the maximum length and width of your pond, it’s time to measure the maximum depth. If you have several depth changes, use the deepest section. If your pond has a flat, level bottom, the job is easy.

Once your pond is dug and it’s time for the sanity check, lay a straight pole from one side of the hole to another and use a straight stick to mark the distance from the pond bottom to the bottom of your board. Take a few measurements and use the longest, making sure it’s within 3-4” inches of your plan.

Note: When using flexible liners, you’ll need to excavate with precision—it’s very difficult to build walls and floor back up and compact the soil enough to provide the necessary support to the liner.

The Apron

Once you have the pond's dimensions, it's time to add an allowance for the apron. The apron is critical because it's what you'll use to anchor the liner in place to prevent leaks, erosion, and other serious problems. Our pond liner calculator will automatically include that allowance, and you can check out section on Anchoring Techniques for details on a variety of anchoring options.

Irregular Shapes or U and L-shaped Ponds

BTL Liners is happy to customize a liner to match your pond’s specific shape and design. We have decades of experience in helping pond owners consider which approach will save money and guarantee a successful installation. Give us a call to discuss details about any custom liner work you need.

Underlayment

If your excavation is properly prepared, underlayment is optional when you’re using reinforced liner materials like BTL’s AquaArmor product. For other materials, like AquaProFlex, we do require the use of underlayment to protect the liner from excessive wear and extend the life of the liner. If you are planning to use underlayment, and you’re able to get it in a single panel, you should order slightly more than your liner—plan on ordering an additional two feet on each dimension to ensure there’s room for anchoring and overlap.

If you’re ordering an underlayment geotextile that will come with a fixed width, and must be overlapped or pieced together on site, plan to order about 1.5 times the square footage of your liner to allow for generous overlaps.

How BTL Calculates Liner Size

You may have noticed that calculating liner size isn’t a simple length by width calculation. Our tool accommodates the room to follow the contours of your pond’s walls, changes in depth, plus an allowance along each edge to allow secure anchoring.

The contrast between pond size and the required liner may be surprising. To help visualize how the liner is laid out, imagine looking at your pond in cross-section. Your liner must travel across the ground starting at about 24 inches from the edge of the excavation, to allow for anchoring. It must follow the walls and contours of the pond, across the bottom, and back up the opposite side, then stretch another 24 inches for anchoring on the opposite side. For the perpendicular measurement, the liner follows the same path.

Sanity Check

Once the hole is dug it’s a good idea to do a sanity check before you begin to install the liner. Precise digging can be challenging, and if your hole is wider or deeper than you planned, you’ll need to make sure your liner will fit. At this stage, you can use a string to follow the contour of the pond at the widest and longest points. After you’ve marked the string, measure it and compare it to the liner size you ordered. If it’s significantly off (12” or more), give your supplier a call and find out your options. BTL Liners has over 100 years of cumulative experience in lining ponds and we’ve helped customers through a host of problems—we’re happy to talk solutions with you!

How BTL Makes it Easy

A Wealth of Experience

Experience and longevity are important when you’re making critical choices such as what materials to choose for your pond, how to keep within budget, and how to manage complex installations. You want to know that your product will be backed by a reliable, experienced team who knows what they’re talking about and knows how to address all those questions that inevitably come up.

BTL Liners started in 1981 as Bend Tarp and Liner, when HDPE, PVC, and EPDM liners were the dominant players in the liner market. These were the days when PVC leached phthalates and EPDM wasn’t always safe for fish. BTL introduced the first double scrim RPE liners to the market, leading the industry in a new, innovative product that was exceptionally strong, durable, lightweight, and quick to install.

Since its early beginnings as a local supplier of tarps and liners, BTL Liners has grown to become a leading supplier of geomembrane systems around the world. Now, in its fifth decade of business, the company boasts over 280 years of combined industry experience among its dedicated staff.

Customer Focus

BTL’s dedication to providing world class customer service is clear from the very first impressions.

- The BTL team is dedicated to treating every customer with respect and friendship, whether they’re a homeowner or the largest company in the country.

- Phone calls are always answered, often on the first ring, by knowledgeable and helpful staff. Within just a few moments, it’s possible to obtain more specialized information from one of their top experts.

- BTL offers free quotes and both online and via phone, according to your preference. Whether you know what you need and just want quick, hassle-free ordering or you are you a new hobbyist or a seasoned professional seeking information on material or complex installations, don’t hesitate to give us a call. We understand how important your project is and we’re happy to discuss the details with you and offer practical advice. Even better, we’ll back up our advice with technical details and real-life experience, all in a friendly, professional manner.

- On BTL’s website, the Information Center is loaded with helpful and informative articles, e-books, and videos. The Question Center is full of hundreds of FAQs to help you with basic research on dozens of topics.

Timely and On-Time

When it comes to completing projects, businesses can’t wait. Time is money, after all, and even a few days delay in receiving your liner equates to lost labor and equipment time, as well as missed deadlines and possibly a ding to your reputation.

For backyard pond owners, a delay in liner delivery is no less devastating. That three-day weekend you painstakingly arranged to install your pond is wasted, then a sudden downpour in the days between excavating your pond and getting the liner installed may spell big problems for your project.

It’s reassuring to know, then, that BTL has always focused on shipping all orders accurately and as quickly as humanly possible. In fact, our liners typically ship within 24 to 48 hours of a confirmed order, sometimes even on the same day.

Our clients often need their geomembrane liners and materials on a short time frame. We maintain large inventories of our products on hand, ready to be cut and shipped. In fact, if your order requires more than 100,000 square feet of material, we can usually ship it within 2-3 days, compared to our competitors, who may need a month or more.

Even custom orders don’t faze us! Unlike many other retailers, BTL liners fabricates orders right here in our own 84,000 square foot facility, allowing us to process custom orders efficiently and produce the largest single panels in the industry.

Budget-Wise

We’re a company made up of practical people who understand the needs of our customers, from individual homeowners to large developers. We specialize in working directly with you to ensure your liner is installed using local resources, including personnel and equipment. Do you have a team of friends willing to help with a weekend installation? We’ll let you know how many you might need. Are you a major contractor planning a series of installations across several developments? We’ll help you evaluate whether it’s better to install each one manually or to bring in a team of professionals.

We’ll never oversell or undersell you just to bring in a sale. Instead, using our team’s vast experience, our goal is always to recommend the most appropriate products and provide a top experience for each customer.

Continuing Support

The challenges of installing a pond don’t stop at measuring and ordering the right size liner. Customers may have questions about storing their shipment, unpacking it, anchoring it, and handling any number of issues, whether complex or straightforward. You’re unlikely to get anything more than scripted responses, if ever get off hold, from an 800 “help” line. BTL Liners is a world apart from those anonymous online retailers. Not only do we answer our phone, but we’re prepared to offer practical advice, instructions, and even diagrams to help you complete a successful installation. We’re proud of our reputation as an industry leader in customer service and we are dedicated to proving ourselves with each customer.

Our liners are carefully packed and shipped to ensure they arrive safely at your location, damage free. Each liner panel includes clear markings and instructions on how to place, unfold, and adjust it, even for large multi-panel installations.

If you’ve ordered a multi-panel liner that needs to be welded on-site, we’ll not only include instructions, but we’ll also point you to helpful videos on our YouTube channel.

Got questions on how to safely anchor your liner? We’ll include diagrams and instructions for the most popular anchor trench method.

Installing under windy conditions? Been there, done that. We have some practical solutions that will make your installation a gentle breeze.

Need something else? Let us know and we’ll do our best to help or point you in the right direction!

Preparing the Site

This rocky soil with many clods will require substantial preparation to make an acceptable subgrade.

Prepared subgrade

In pond construction, the term subgrade refers to the soil found at the bottom of an excavation. It’s what will support the pond liner and, in turn, the weight of the water it contains. It’s a critical part of the overall pond structure and it deserves careful preparation to ensure that the pond has a long, problem-free life.

So why does the subgrade matter so much? Consider the weight of water pressing incessantly on the floor of a pond and on the liner itself, year after year. In a perfectly prepared subgrade, this pressure is passed directly and evenly to the underlying soil without exerting stress or strain on the liner. This is the ideal situation since, without excess stress or external damage, a liner can last virtually forever.

To maximize the life of a pond liner, then, the soil at the bottom and sides of the excavation must be carefully prepared so there is full, even contact between the liner and the underlying soil, with no protrusions, voids, or low areas.

What Makes a Good Subgrade?

Subgrades are important, but fortunately, they aren’t that complicated. Most soils such as fine-grained sand, loam, and clay serve just fine as subgrade if all rocks, sharp roots, or other materials that can puncture or put uneven pressure on the liner are removed. In addition, voids or soft spots should be filled and compacted. An ideal subgrade will be composed of fine-grained soil or sand that has been carefully compacted, is uniformly flat, free of excess moisture, and should not have any object, whether foreign or natural, that protrudes above the surface of the subgrade.

How to Prepare a Subgrade

As you finish excavating your pond, sift through the soil and remove any large or sharp rocks, sticks, organic material, and foreign objects. Using a rake, break up any large clods. A few small, smooth, rounded stones can remain, but they should be compacted into the subgrade so that nothing protrudes above the surface. After compacting, if any stones, clods, or other objects (of any size) are still protruding above the level of the subgrade, they should be removed.

Any voids, holes, soft spots, pockets, or dips in the subgrade should be completely filled with earth or sand and carefully compacted. There should be no areas where the liner must bridge a gap or support a soft spot. The finished subgrade should be smooth and even - no ruts or tracks left by equipment, for example.

Once the subgrade has been cleared, check it for protrusions - anything that sticks up above the level of the surrounding dirt must go, even if it’s a smooth rock. Level and even are the keywords here!

If you’re working in the wintertime, make sure there’s no ice or lumps of frost. Those will eventually melt, of course, but then you’ll have excess moisture and a void or soft spot beneath the liner, which can cause problems in the future.

Ideally, you’ll be able to complete your excavation within a day or two (depending on how large it is), which will help ensure that it doesn’t dry out too much or, even worse, get drenched or flooded in a storm. If, for some reason, there is standing water in your excavation, be sure to remove it completely.

A Note About Standing Water

Standing water in a pond excavation is an indicator of big problems to come and should trigger a full stop in your installation efforts so the source can be identified and you can deal with it effectively before it becomes a disaster.

Standing water, if it’s not 100% attributable to last night’s rainstorm, had to come from somewhere. If your area received 0.75 inches of rain but you have 1.2 inches of rain in your excavation, that indicates that your pond is receiving drainage from somewhere - perhaps it’s situated downslope of another part of your yard?

Surface Water Runoff

All in all, runoff from rain is not a complete disaster, but it definitely requires a solution. Surface drainage may travel miles before it ends up in your pond and will inevitably bring a variety of unwelcome contaminants into your pond - fertilizers, pesticides, animal droppings, and road pollutants, not to mention silt, grass clippings, and other debris. Even clean rainwater will raise the pH of your pond, if there’s enough of it in a short amount of time. It’s not possible to detect or correct for possible contaminants or constantly monitor the changing water chemistry, especially during a rainy season, but when the result can be unpleasant algae blooms or even plant and fish death, a few ounces of prevention are well worth it.

If your pond excavation is showing signs of receiving surface drainage, spend some time examining the flow pattern and install some sort of diversion to keep that water out of your pond. Berms (small walls) and French drains are excellent choices that can be attractive and don’t need to be incredibly expensive. Berms constructed of brick or stone are popular solutions. There may even be an opportunity to install a decorative stone berm that doubles as a bench for viewing fish up close. The berm should extend at least a foot below ground and several inches higher than the ground on the upslope side so that water flows around the berm instead of over it.

A planted border coupled with a French drain can also be an attractive solution if there is no significant slope carrying water to your pond. French drains are simple structures that involve digging a ditch several feet outside the edge of the pond and installing corrugated perforated pipe. The ditch should extend around the sides of the pond and release the captured flow into a well-drained area of the yard. The ditch itself can be filled with gravel, and native grasses or plants can help beautify the area as well as help take up excess moisture.

A High Water Table

If your pond has standing water even though the weather has been dry, you’re looking at a much more serious problem. Water seeping up from the ground indicates that you may have inadvertently tapped into your local water table. That may sound like a happy accident, in the words of Bob Ross, but in reality, it’s a lot more complicated than that. Aside from all the questions about permitting and use of public waters, there are important practical matters to consider before you embrace this windfall: