Establishing a New Vineyard with Inter-Row Weed Control and Soil Stabilization

The Challenge

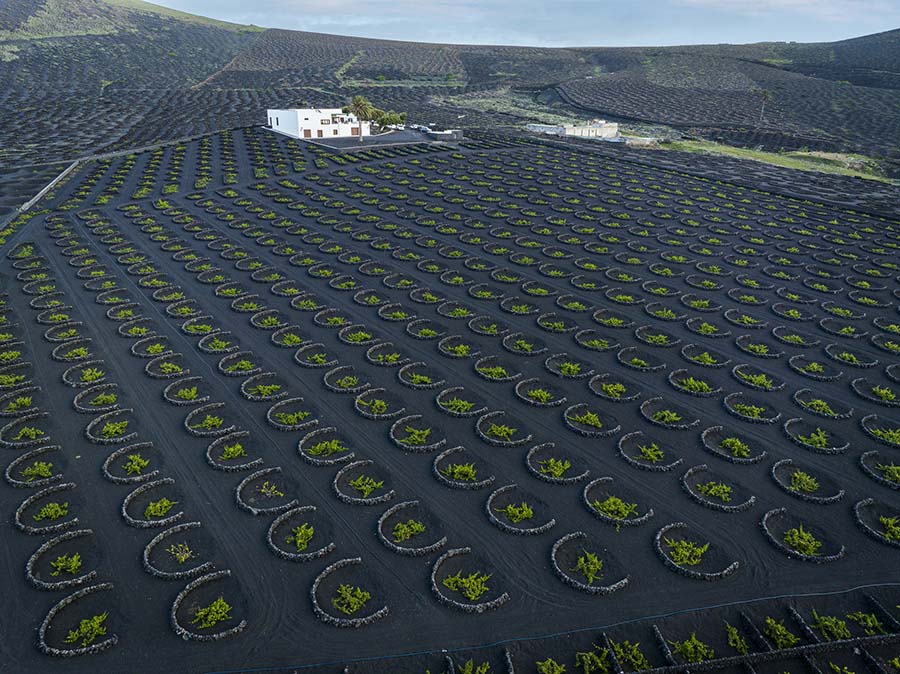

A grower is establishing a new 10-acre vineyard on a site with a history of significant annual weed pressure and includes some sections with mild slopes (5-8% grade). During the critical first 3-5 years, key goals are to ensure vigorous young vine growth by minimizing weed competition, reduce reliance on herbicides and manual weeding in the inter-rows (the drive rows between vine rows), and prevent soil erosion.

The Agrotextile System Solution

After preparing the field and planting the young vines, the grower decides to install a durable, UV-stabilized heavy-weight slit film woven agrotextile system (4.0 oz/SY) in all the inter-row alleyways. This choice reflects the long-term nature of the vineyard and the need for resilience in trafficked inter-rows. The fabric is laid out carefully, ensuring good soil contact, and securely anchored, especially on the sloped sections, with 12-inch overlaps at all seams. Planting holes for cover crops within the vine row are managed separately.

Projected Impacts & Benefits

Reduced Weed Competition & Herbicide Use

From the first year, the agrotextile system almost entirely eliminates weed growth in the inter-rows. This drastically reduces the young vines’ competition for water and nutrients, promoting healthier root development and canopy growth. The need for herbicide spray passes in the inter-rows is cut by an estimated 80-90% annually for the first 3-5 years, leading to significant cost savings on materials and application labor.

Labor Savings

Substantially reduced weed pressure means manual weeding or mechanical cultivation in the inter-rows is almost entirely unnecessary. This frees up hundreds of labor hours annually, which can be redirected to critical vine training and other vineyard management tasks.

Enhanced Vine Establishment

Young vines establish more quickly and vigorously with reduced competition and a more stable inter-row environment. This can lead to earlier first harvests and better long-term vineyard productivity.

Soil Stabilization and Erosion Control

On the sloped sections, the agrotextile system immediately shields the soil surface from rain impact and water runoff. Soil erosion in the inter-rows is visibly minimized, preventing the formation of rills or gullies and conserving valuable topsoil. This also creates safe, stable pathways for equipment and foot traffic and helps maintain the integrity of the inter-row surface over many years.

Outcome

By establishing the new vineyard with an integrated agrotextile system, the grower anticipates significant operational savings in weed management, healthier, more uniformly established vines, and improved soil conservation. These key factors are strong indicators for their vineyard's long-term success and sustainability.

Improving Soil Health in a No-Till Organic Vegetable System

The Challenge

An organic vegetable farmer manages 5 acres using a no-till system with permanent raised beds. Their primary goals are continuously improving soil health (structure, organic matter, biological activity) and managing weeds effectively without tillage, minimizing soil disturbance to protect the soil ecosystem they’ve been building.

The Agrotextile System Solution

The farmer decides to implement a long-term strategy using durable, UV-stabilized slit film woven agrotextile to cover the surfaces of their permanent vegetable beds. After shaping and amending the beds, the fabric is laid out, cut to fit, and securely anchored. Crops are then transplanted or direct-seeded into precisely cut holes in the fabric. This installation will remain in place for several seasons, aligning with the permanent bed, no-till philosophy.

Projected Impacts & Benefits on Soil Health

Protecting Soil Structure

The agrotextile provides a protective shield for the bed surface, buffering the soil from the impact of heavy rainfall, preventing soil crusting and compaction. This buffer is crucial in a no-till system where good soil structure, once developed, needs to be preserved.

Optimized Soil Moisture

By significantly reducing surface evaporation, the fabric helps maintain more consistent and optimal soil moisture levels within the beds. A stable moisture environment is highly beneficial for the proliferation and activity of soil microorganisms (bacteria, fungi) and earthworms, which are key drivers of nutrient cycling and soil organic matter formation in organic systems.

Weed Suppression without Tillage

The slit-film geotextile provides excellent weed control directly on the bed tops, drastically reducing the need for hand-weeding and eliminating the need for any tillage for weed management post-installation. Maintaining the no-till principle is fundamental for preventing oxidation and loss of organic matter and protecting the delicate soil food web.

Enhanced Soil Organic Matter (SOM) Dynamics

With reduced soil disturbance and consistent moisture, plus the continuous addition of organic matter as the root systems of prior crops decompose undisturbed, conditions become highly favorable for the gradual accumulation or preservation of soil organic matter. The fabric also protects any surface-applied organic mulches (like compost spread around planting holes) from rapid decomposition or weed infestation.

Improved Soil Tilth

Over time, the combination of no disturbance, stable moisture, and thriving biological activity fostered by the agrotextile system improves soil aggregation and friability, making the beds easier to work with for subsequent plantings.

Outcome

For this organic no-till grower, the agrotextile system is a key tool in their soil health management strategy. It helps create and maintain a stable, protected, and biologically active soil environment, supporting their long-term goals for sustainable and productive vegetable cultivation.

Addressing Common Challenges and Considerations

While agrotextile systems offer substantial benefits, like any farming tool, occasional challenges can arise. Proactive awareness and good management practices can effectively address most of these:

Managing Aggressive Perennial Weeds

Challenge

Tough perennials (e.g., nutsedge, bindweed) might occasionally try to penetrate lighter-weight fabrics, exploit seams, or emerge through planting holes. Weeds can also root in soil/debris accumulated on top.

Considerations

Thorough site preparation to reduce existing perennial pressure before installation is critical. Using a durable, heavier-weight fabric, ensuring secure 12-inch overlaps, and promptly spot-treating or hand-pulling any escapees prevents establishment. Keeping the fabric surface clean also discourages on-top weed growth.

Surface Water Runoff or Ponding

Challenge

While slit films are designed to be permeable, extremely heavy rain on highly compacted fabric, or on fabric laid on poorly drained or steeply sloped ground, might lead to temporary surface ponding or excess runoff if infiltration is slow.

Considerations

Ensure good underlying soil drainage and appropriate site grading before installation. Keep the fabric clean of debris that might clog pores. On slight slopes, shingle overlaps correctly to direct water flow. In very prone areas, slight crowning of beds beneath the fabric can aid water shedding.

End-of-Season Management for Annual Crops

Challenge

Deciding how to handle the fabric if annual crop rotations require significant soil reworking between seasons.

Considerations

Ideally, for multi-year systems, leave the fabric in place and plant subsequent annuals into new or existing holes to maximize ROI and soil health benefits. If removal is essential for your rotation, carefully detach anchors, clean the fabric thoroughly, ensure it's completely dry, then roll and store it protected from UV light and pests for future reuse. Factor in the labor for removal/reinstallation versus leaving it in situ.

Slipperiness When Wet or Frosty:

Challenge

The surface of some woven agrotextiles can become slippery when wet, icy, or covered in frost.

Considerations

Exercise caution when walking on the fabric in these conditions, especially on slopes. Ensure appropriate, slip-resistant footwear is worn by all farm staff.

Conclusion: A Smart Investment for Your Farm's Future

Throughout this guide, we’ve journeyed from the fundamental benefits of slit film woven agrotextile systems to practical steps for their selection, installation, and long-term care. We’ve explored their economic advantages and contributions to soil health and water conservation. Through practical scenarios, we’ve seen how they can be effectively integrated into diverse commercial farming operations.

Introducing an agrotextile system to your farm is about working smarter, not just harder, particularly when it comes to managing weeds. It’s a practical investment that keeps weeds in check, slashes labor hours, improves water use efficiency, fosters healthy crop conditions, and ultimately improves your farm’s bottom line.

As you consider the unique challenges and opportunities on your own farm, we hope this guide has given you the knowledge and confidence to evaluate how a well-chosen and properly managed agrotextile system can become a powerful ally in pursuing sustainable and successful farming.