Silage Cover Weighting: A Heavy-Duty Task

Think of it like cooking food for your family. You wouldn't leave the ingredients uncovered on the counter, exposed to flies and dust, would you? The same goes for silage. No matter how good your cover is, it will only do its job if it's properly secured.

This article will explore the ins and outs of silage cover weighting. It will consider different weighting methods, the factors that affect how much weight you need, and practical tips for keeping your silage safe and sound.

Holding it Down: Silage Cover Weighting Methods

Weighing down silage cover is like anchoring a tent – it must be secure enough to withstand a storm and stay in place. The best method for you will depend on things like the type of silo you have, the cover material, and the weather conditions in your area. Let's explore some common options.

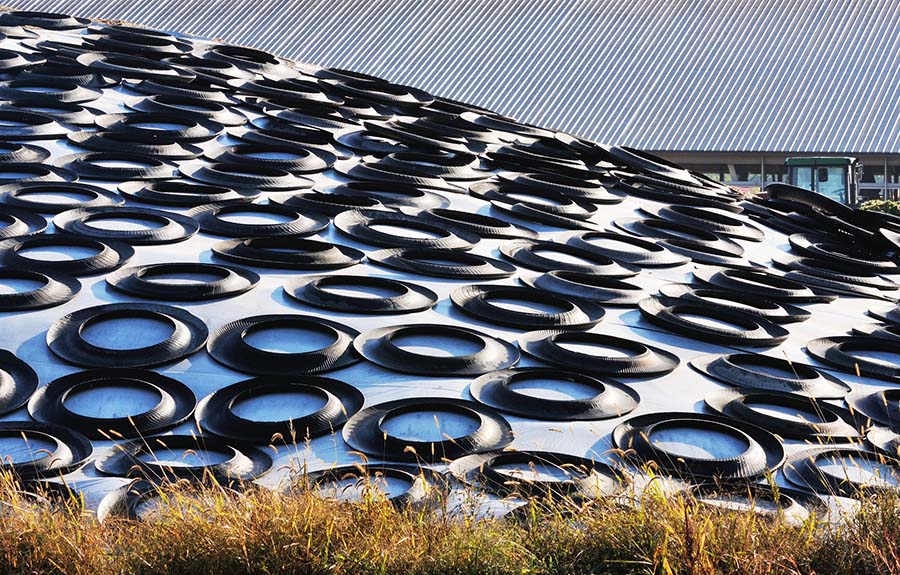

Tires: A Classic Choice

Tires are a popular pick for weighing down silage covers. They're easy to find, budget-friendly, and do a good job of distributing weight. Plus, they're easy to stack and interlock for extra stability. However, tires can be a pain to store and move around, and they can break down over time if left in the sun. They can also become a haven for pests if not kept clean.

Tips for Using Tires

- Spread them evenly across the cover in a staggered pattern, like bricks in a wall.

- Pay extra attention to the edges and corners where the wind can sneak in. Use bigger tires or additional weight in these areas.

- Cover the entire surface to prevent gaps and air pockets.

Sandbags/Gravel Bags: Customizable Weights

Sandbags or gravel bags are great options because you can adjust the weight for a perfect balance. They're also relatively easy to store. However, they can be more expensive than tires and may need replacing more often, especially if they get wet. Filling and placing the bags can also be a chore.

Tips for Using Sandbags/Gravel Bags

- Distribute the bags evenly across the cover, close together, with minimal gaps.

- Use a staggered pattern, like with tires, for better coverage.

- Smaller bags are easier to handle and allow for more precise weight distribution.

Other Options to Consider

- Concrete blocks are heavy and durable but can be challenging to handle and could damage your cover.

- Water-filled tubes can be adjusted and easily conform to the shape of the cover, but they can leak and may freeze in cold weather.

- Some companies offer custom weights designed for silage covers. These can be pricier but may offer advantages in weight distribution and ease of use.

Choosing the Right Method

The best weighting method depends on your needs and circumstances.

- Vertical silos often require less weight than horizontal ones due to the downward pressure of the silage.

- Heavier covers may require less weight than lighter covers.

- Windy environments need more weight to prevent cover uplift.

- Factor in the time and effort it takes to fill, place, retrieve, and maintain the weights.

Weighting Woes: Mistakes to Avoid

Weighting a silage cover might seem simple, but some common blunders can spell disaster for your silage. Let's take a look at these pitfalls and how to avoid them.

Not Enough Weight: A Recipe for Disaster

One of the biggest mistakes is not using enough weight. This mistake can lead to "wind uplift," where the wind gets under the cover and causes it to flap or even tear. A displaced cover exposes your silage to oxygen, which can lead to spoilage. Not having enough weight can also allow air pockets to form under the cover, creating cozy spots for those pesky spoilage microorganisms.

Uneven Weight Distribution: Stressing Out Your Cover

Spreading the weight evenly across the cover is essential. Uneven weight distribution can put too much stress on specific areas, leading to tears or punctures. It can also create gaps in the seal, allowing oxygen to sneak in.

Wrong Materials: Choose Wisely!

Not everything is suitable for weighing down a silage cover. Avoid using:

- Sharp objects that can puncture the cover.

- Materials like hay bales or wood that can absorb moisture and become too heavy.

- Loose debris, such as branches or leaves, that can blow away.

Edges and Corners: The Trouble Spots

The edges and corners of your silage cover are weak points. They need extra attention because they're more vulnerable to wind uplift. Neglecting these areas can lead to gaps and oxygen exposure.

Maintenance Matters: Keeping a Watchful Eye

Weighting your silage cover isn't a "set it and forget it" task. You need to check it regularly to be sure everything is in place and in good condition.

- Inspect the cover and weights for signs of damage, shifting, or wear and tear.

- Adjust the weights as needed to maintain even distribution and prevent gaps.

- Replace any damaged or worn-out weights promptly.

Protecting Your Investment

A properly weighted silage cover makes a big difference in the quality of your feed. It helps reduce spoilage, maintains the quality of your feed, protects your investment, and ultimately, boosts your bottom line.